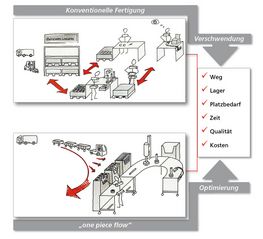

One piece flow – the workplace is optimised for the production process

What does one-piece flow mean?

The one-piece flow principle is also referred to as employee-centred workflow. With conventional conveyor belt manufacturing the same task is always carried out at a fixed station. For example, fifty gear units are manufactured bit by bit in individual steps. A lot of time passes by in which the company does not earn any money and any production defects are not noticed until very late when a large number of gear units have already been completed. The rectification work on the 50 products is very time-consuming and costly.

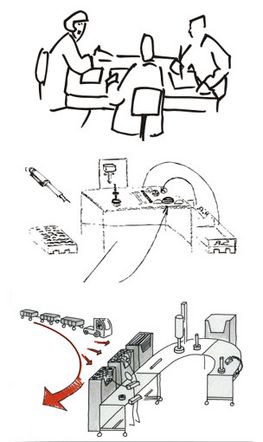

With one-piece flow on the other hand the employee accompanies the workpiece through the individual assembly/processing steps and has to have a command of all work processes. The idea behind this: to reduce lapses in concentration caused by monotony and to increase motivation by way of variety. The quality/functional check is performed after every single final product and this is much earlier than the sale.

Characteristics of a one-piece flow workstation:

- Quicker quality feedback

- More flexible response to customers' needs

- Less space required

- Reduction in inventory and intermediate storage

- Shorter processing times

- Increased productivity

- Interesting working environment

- Reduction in overall costs

- Ergonomic workplace

Our service – expert consultation also available on-site

If you want to focus your resources on other tasks and are looking for an expert partner you can rely on, our specialists will work closely with you to develop tailor-made solutions.

- Field service – on-site consultation also available

Our key account managers and sales consultants are happy to visit you on-site and help you draw up practical solutions. - Just make a sketch of your requirements

- Workshop – definition of the required components

- Our product specialists will devise a solution for you

- Implementation and delivery

We can deliver your turnkey solution or assemble and commission it for you on-site.

The LEAN workstation systems can be upgraded with a wide range of assistance systems:

Pick to light workstationsFind out more Poka-yoke workstation

Find out more Workstation with camera-based assistance system

Find out more