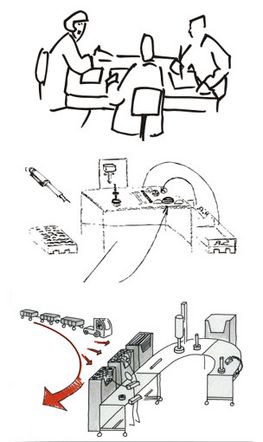

Poka-yoke manual picking and assembly workstations

The employee is guided step by step to the correct component container by the opening of the flaps and the lighting up of the display

Poka-yoke = error prevention

When it comes to installing components at manual workstations the supplied components are picked manually. In the process, it is almost inevitable that incorrect components are picked and installed as a result of the routine of the employees. As the complexity and variety of the components being installed increases, the likelihood of incorrectly picked components also increases.

Errors can simply be avoided with guided production solutions

Typical sources of errors in manual assembly include the picking of incorrect components with a similar appearance or name, picking and installation of components in the wrong order or the simple omission of a component. A quality inspection which is conducted after production is not suitable for preventing defects during assembly. Repair or rectification is considerably more costly and time-consuming or, in the worst case, the customer receives incorrectly assembled products.

A poka-yoke assembly workstation represents a solution to these problems. The poka-yoke principle is a Japanese designation which can be loosely translated as "error prevention". Poka-yoke is a method for preventing errors during production or in logistics at the source before they even have a chance to occur and cause unforeseeable costs.

Download (PDF)

Jobs and work instructions can be called up via a display screen. How to access and pick the required materials is stated step by step. Flawless material replenishment is ensured.

The poka-yoke zero defect principle

When it comes to assembly at workstations, the supplied components are picked manually. In the process, it is almost inevitable that incorrect elements are picked and installed as a result of the routine of the employees. As the complexity and variety of the components being installed increases, the likelihood of incorrectly picked elements also increases.

Poka-yoke workstations also provide a physical barrier (hinged doors) in addition to the visual aids of the classic pick to light system so that incorrect parts cannot be picked even inadvertently.

The employee is guided step by step to the correct component container by the opening of the flaps and the lighting up of the display. The materials required for the working step are picked and there is no need for a long search. Poka-yoke sensors/flaps are also used for material replenishment. This ensures that the correct materials are supplied and installed. The individual working steps can be shown on a display screen.

The benefits of the poka-yoke workstations at a glance:

- Zero defects in assembly

- Productivity is increased considerably

- Process reliability even with multiple product variants

- New employees are trained and productive within a few minutes

- Consistent quality regardless of the employee, no rectification or repair

- No parts lists or instructions on paper

- No searching for components

- Short assembly times

Our service – expert consultation also available on-site

Our product specialists are of course on hand to help you when it comes to detailed issues, and we develop the perfectly tailored solution for your processes together with you.

We assist you from the first review right through to commissioning – your partner for process optimisation!

- Field service – on-site consultation also available

Our Key Account managers and sales consultants are happy to visit you on-site and help you draw up practical solutions. - Just make a sketch of your requirements

- Workshop – definition of the required components

- Our product specialists will devise a solution for you

- Implementation and delivery

We can deliver your turnkey solution or assemble and commission it for you on-site.

Further assistance systems for the optimisation of assembly processes:

Find out more Workstation with camera-based assistance system

Find out more