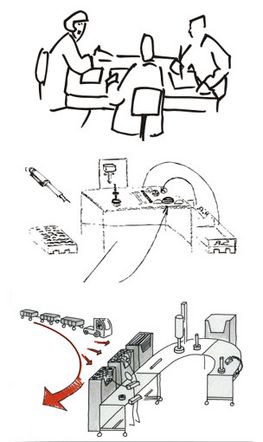

Collaborative robots (cobots) provide support for the assembly process

Cobots provide support at manual workstations

Cobots can provide assembly employees with support in many ways: cobots lift heavy objects or take on monotonous tasks with single-sided strain, like accurately handing over parts. This way, they provide relief for workers and protect their health. Collaborative robots are also a practical option for line-controlled tasks which a human can either not perform as precisely, continuously or quickly and reliably as a machine. In conjunction with height workstations and assistance systems, they open up completely new assembly concepts.

The benefits of the workstations with cobot integration at a glance:

- Physical relief (lifting heavy loads, monotonous tasks) for the employee

- Feeding and forwarding of components

- The range of action of cobots can be expanded considerably using linear units and lifting columns

- Combination with other assistance systems possible

When it comes to equipping assembly workstations with cobots or poka-yoke systems, RK-AHT collaborates with Mitsubishi Electric

Linear technology expands the range of cobots

A seventh or further additional axles can be added to the six drive axles of a collaborative robot in order to expand its range of action. The expansion of the range of action can be achieved, for instance, using RK Rose+Krieger linear technology. Lifting columns, such as the RK Powerlift can thus be used for the electrical height adjustment of the cobot (Y-axis). Linear actuators additionally position the cobot on the X- and Z-axis and thus expand its range, for example, in order to link multiple workstations or storage spaces. These linear actuators can in theory be of any length. The specialists at RK Antriebs- und Handhabungs-Technik will help you with design and system integration for the linear units and lifting columns.

Specialist support for your production/assembly process

The scope for use of cobots is enormous. It covers everything from standalone solutions and material feeding and removal to complex three-dimensional gantries for welding applications.

Before installation and integration of the cobot in the production environment, it makes a lot of sense to consult a specialist.

Depending on the complexity of the project we work together, for example, with the experts for the development of (semi) automatic processes of the Fraunhofer IEM or the manufacturer of cobots, Mitsubishi Electric. Because, even though a small cobot may be a lower investment than an industrial robot, it is still important to make sure that it is a profitable investment and will amortise within the budgeted period.

Contact us when planning your next project and we will get our project specialists together around the table to offer you a solution ideally tailored to the process.